Applicators, Crimping Tools & Applicator Spares Manufacturer

Applicators, Crimping Tools & Applicator Spares

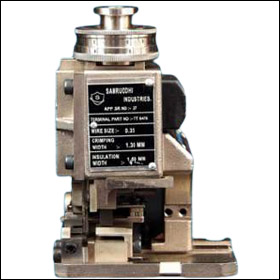

Side Feed Applicators

Crimping Height :135.8 mm

Stroke: 40 / 30 mm

Terminal Pitch : < 35 to 40 mm

Wire Size : Max 6 mm2 (9 AWG)

Weight : 3.15 Kg

Dimensions : W144 x H14, 5 x D190

End Feed Applicators

Crimping Height :135.8 mm

Stroke: 40 / 30 mm

Terminal Pitch : < 35 to 40 mm

Wire Size : Max 6 mm2 (9 AWG)

Weight : 3.15 Kg

Dimensions : W144 x H14, 5 x D190

Flag Terminator Applicator

Crimping Height :135.8 mm

Stroke: 40 / 30 mm

Terminal Pitch : < 35 to 40 mm

Wire Size : Max 6 mm2 (9 AWG)

Weight : 3.700 Kg

Dimensions : W144 x H14, 5 x D220

Joint Terminal Applicators

Crimping Height :135.8 mm

Stroke: 40 / 30 mm

Terminal Pitch : < 35 to 40 mm

Wire Size : Max 6 mm2 (9 AWG)

Weight : 3.15 Kg

Dimensions : W144 x H14, 5 x D190

Crimping Tools

These tools are perfect, absolutely top quality & work very well. All tools are good functioning and suit with our applicators.

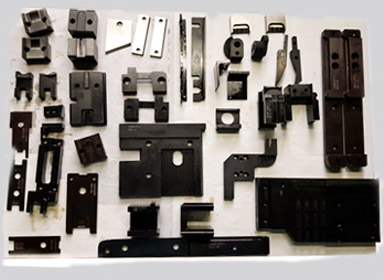

All Applicator Shield Parts

All type tool checking in house for quality needed.

Dial

Set the top adjusting dial according to the values specify by customer in cross-section-report.

The top dial has a range of 2.2 MM with resolution of MM 0.01, every stop etched on its edge -moves the crimpers 0.01 MM Up or Down.

Since we are aiming at 0.65 We have to set the adjusting ring of the closet number to 0.65 which is 08 equivalents to an index value 6.

As we want 0.65 we have to turn the top adjusting dial five more steps ( 0.01 + 0.01 + 0.01 + 0.01 + 0.01 = 0.05 ) to get our result ( 0.60 + 0.05 = 0.65 ).

Notes ( Both dials adjustment is clockwise direction. )

How to adjust insulation crimping height ?

To set the correct insulation crimping height follow the same procedure described above for the wire crimping height.

If no data are available regarding the insulation crimping height set the bottom dial to ' 0 ' turn it clockwise until the resulting crimping is deemed correct.

Tooling & Spare Parts